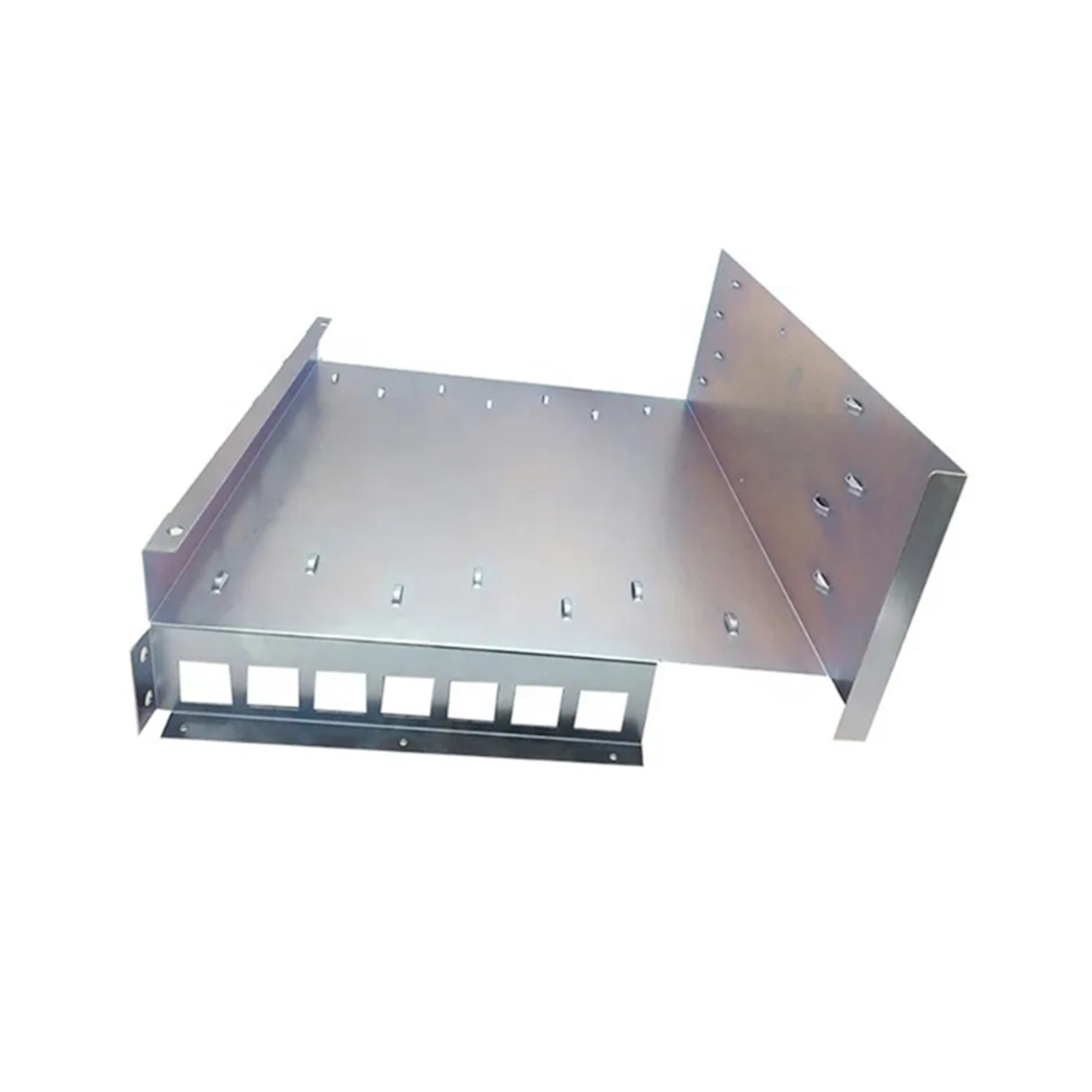

Tsika aruminiyamu simbi inokotama kutsika zvikamu zvemarata bracket

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. Kupfuura makore gumiyehunyanzvi hwekutengeserana mhiri kwemakungwa.

2. Ipaone-stop servicekubva pakugadzira mold kusvika kune chigadzirwa.

3. Kurumidza kuburitsa nguva, nezve30-40 mazuva. In stock mukati mevhiki imwe.

4. Yakasimba yemhando yekutonga uye maitiro ekugadzirisa (ISOcertified mugadziri uye fekitori).

5. Mimwe mitengo inonzwisisika.

6. Nyanzvi, fekitari yedu inekupfuura 10makore enhoroondo mumunda wesimbi stamping sheet simbi.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Product Advantages

Zvakanakira zvealuminium stamping zvikamu zvinonyanya kuratidzwa mune zvinotevera zvinhu:

1. Yakanakisa zvinhu zvekushandisa: Aluminium ine yakaderera density uye kureruka uremu, asi ine yakanaka ductility uye machinability, saka yakanyatsokodzera stamping processing. Panguva imwecheteyo, aluminium alloy stamping zvikamu zvine purasitiki yakanaka kwazvo uye inogona kudhonzwa mumafilaments uye yakakungurutswa mumafoiri, ayo anogona kusangana nezvinodiwa zvekugadzira zvakasiyana-siyana zvakaoma maumbirwo uye zvimiro.

2. Yakanakisa corrosion resistance: Aluminium alloys anoratidza kumira zvakanaka kwekuora pakupisa kwekamuri uye haisi nyore kukanganiswa nemakemikari akadai seacids uye alkalis. Naizvozvo, zvikamu zvealuminium stamping zvinogona kuchengetedza kuita kwakagadzikana kunyangwe munzvimbo dzakaoma.

3. Yakanaka magetsi uye inopisa conductivity: Aruminiyamu alloys ane yakanaka magetsi uye thermal conductivity, iyo inoita aluminium stamping zvikamu zvinowanzoshandiswa mumagetsi, midziyo yemagetsi nemimwe minda.

4. Kubudirira kwekugadzira maitiro: Iyo stamping process inogona kuwanda-kuburitsa aruminiyamu stamping zvikamu zvine hunyanzvi hwekugadzira uye mutengo wakaderera. Panguva imwecheteyo, dhizaini inogona zvakare kuve nechokwadi cheiyo dimensional kurongeka uye pamusoro pemhando yezvikamu, kusangana nezvinodiwa zvehupamhi hwepamusoro uye hwemhando yepamusoro.

5. Yakasiyana-siyana yekushandiswa: Aluminium stampings anoshandiswa zvakanyanya mukugadzira motokari, kugadzirwa kwemidziyo yemumba, midziyo yemagetsi, kugadzirwa kwemichina, maelevator accessories, uye aerospace. Semuenzaniso, anogona kushandiswa mukugadzira magomba emuviri, mapaneru emagonhi, magomba emuchina wekuwachisa, magomba efiriji, maredhiyata, mabhuraketi, mota dzekusimudza, njanji, zvidhinha uye zvimwe zvigadzirwa.

Aluminium alloy pachayo ine hunhu hwekureruka, kusimba, nyore kugadzirisa uye kushora kuramba, izvo zvinoita kuti ive chinhu chakanaka chekugadzira. Kuburikidza neiyo stamping process, aruminiyamu stamping ane maumbirwo akaomarara uye chaiwo madiki anogona kugadzirwa.

FAQ

Q1: Kana isu tisina chero mifananidzo, chii chatinofanira kuita?

A1: Kuti tikwanise kutevedzera kana kukupa mhinduro dzepamusoro, nemutsa tumira sampuro yako kumugadziri wedu. Titumirei mapikicha kana madhiramu anosanganisira zviyero zvinotevera: ukobvu, kureba, kureba, uye hupamhi. Kana iwe ukaisa odha, CAD kana 3D faira ichagadzirirwa iwe.

Q2: Chii chinokutsaura kubva kune vamwe?

A2: 1) Rubatsiro Rwedu Rwepamusoro Kana tikawana ruzivo rwakakwana mukati memaawa ebhizinesi, tichaendesa iyo quotation mukati memaawa makumi mana nemasere.

2) Yedu yekukurumidza kutendeuka kwekugadzira Isu tinovimbisa 3-4 mavhiki ekugadzirwa kweodha yenguva dzose. Sefekitari, tinokwanisa kuvimbisa zuva rekutumira sekutsanangurwa kwazvino muchibvumirano chepamutemo.

Q3: Zvinogoneka here kuona kuti zvigadzirwa zvangu zviri kutengeswa sei pasina kushanyira bhizinesi rako?

A3: Isu tinopa yakakwana yekugadzira hurongwa pamwe nemishumo yevhiki nevhiki inosanganisira mifananidzo kana mavhidhiyo anoratidza mamiriro emuchina.

Q4: Zvinoita here kugashira samples kana muedzo wekuti zvinhu zvishoma chete?

A4: Nekuti chigadzirwa chakasarudzika uye chinoda kugadzirwa, isu tichabhadharisa sampuli. Zvisinei, kana sampuli isingadhuri kudarika kurongeka kwehuwandu, tichadzorera mari yemuenzaniso.