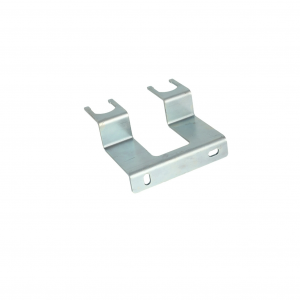

Tsika Anodized Aluminium Zvikamu zvakadhindwa Zvikamu

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Mhando dzezvitambi

Isu tinopa single uye multistage, inofambira mberi kufa, yakadzika dhizaini, fourslide, uye dzimwe nzira dzekutsikisa kuti ive nechokwadi chenzira inoshanda yekugadzira zvigadzirwa zvako. Nyanzvi dzeXinzhe dzinogona kuenzanisa purojekiti yako nekutsikirira kwakakodzera nekuongorora yako yakarodha 3D modhi uye tekinoroji kudhirowa.

- Progressive Die Stamping inoshandisa akawanda anofa uye nhanho kugadzira zvakadzika zvikamu kupfuura zvazvingawanzo kuwanikwa kuburikidza nekufa kwega. Iyo zvakare inogonesa akawanda geometries pachikamu sezvavanoenda kuburikidza nekufa kwakasiyana. Iyi tekinoroji yakanyatsokodzera vhoriyamu yepamusoro uye zvikamu zvakakura senge izvo zviri muindasitiri yemotokari. Transfer die stamping ibasa rakafanana, kunze kwekufambira mberi kwekufa kutsika kunosanganisira workpiece yakasungirirwa kune simbi tambo yakadhonzwa mukati memaitiro ese. Transfer die stamping inobvisa workpiece uye inoifambisa pamwe chete neconveyor.

- Deep Draw Stamping inogadzira zvitambi zvine makomba akadzika, semakona akavharirwa. Iyi nzira inogadzira zvimedu zvakaomarara sezvo iyo yakanyanyisa deformation yesimbi inomanikidza chimiro chayo kuita imwe crystalline fomu. Yakajairwa dhizaini stamping, iyo inosanganisira isina kudzika inofa inoshandiswa kugadzira simbi, inowanzoshandiswa.

- Fourslide Stamping inogadzira zvikamu kubva kumatemo mana pane kubva kune rimwe divi. Iyi nzira inoshandiswa kugadzira tunhu tudiki twakaoma kunzwisisa kusanganisira zvemagetsi zvakaita semabhatiri enhare. Kupa mamwe dhizaini kuchinjika, kuderera kwemitengo yekugadzira, uye nekukurumidza nguva yekugadzira, mana-slide stamping yakakurumbira mune aerospace, zvekurapa, zvemotokari, uye zvemagetsi maindasitiri.

- Hydroforming ndiyo shanduko yekutsika. Mashizha anoiswa padhishi rine chimiro chepasi, nepo chimiro chepamusoro chiri dundira remafuta anozadza kusvika pakumanikidzwa kukuru, achidzvanya simbi muchimiro chepasi kufa. Zvikamu zvakawanda zvinogona kuve hydroformed panguva imwe chete. Hydroforming inzira inokurumidza uye yakaringana, kunyangwe ichida chidimbu kufa kucheka zvikamu kubva papepa mushure.

- Blanking inocheka zvidimbu kubva papepa sedanho rekutanga usati wagadzira. Fineblanking, shanduko yekuvharika, inoita kucheka chaiko nemakona akatsetseka uye nzvimbo yakati sandara.

- Coining ndeimwe mhando yekuvharika iyo inogadzira madiki akatenderera workpieces. Sezvo ichibatanidza simba guru kuumba chidimbu chiduku, inoomesa simbi uye inobvisa maburrs uye mipendero yakaoma.

- Kurovera kunopesana nekuvharisa; zvinosanganisira kubvisa zvinhu kubva pakushanda panzvimbo yekubvisa zvinhu kuti ugadzire workpiece.

- Embossing inogadzira matatu-dimensional dhizaini musimbi, ingave yakasimudzwa pamusoro pepamusoro kana kuburikidza nenhevedzano yekuora mwoyo.

- Kubhenda kunoitika pane imwe axis uye inowanzo shandiswa kugadzira maprofile muU, V, kana L maumbirwo. Iyi nzira inoitwa nekukochekera rimwe divi uye kukotamisa rimwe pamusoro pefa kana kudzvanya simbi mukati kana kurwisa kufa. Flanging ndiko kukotama kwematabhu kana zvikamu zvebasa rekushanda pachinzvimbo chechikamu chose.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Surface kurapwa maitiro ealuminium stamping zvikamu:

Muindasitiri yekutsikisa, aluminium stamping zvikamu zvakare yakajairika simbi stamping chikamu. Nzira dzakajairika dzekurapa pamusoro pealuminium stamping zvikamu ndeidzi:

1.Anodizing

Anodizing inogona kunyatso gadzirisa kushomeka kwekuoma kwepamusoro uye kupfeka kuramba kwealuminium stamping zvikamu. Inogonawo kuwedzera zvakanyanya nguva yekushandisa yealuminium stamping zvikamu uye kuita kuti chigadzirwa chitaridzike chakanyanya kunaka. Nhasi, anodizing yave inowanzoshandiswa pamusoro pekurapa nzira yealuminium stamping zvigadzirwa. Anodizing inoreva electrochemical oxidation yesimbi kana alloys. Aluminium nema alloys ayo anoumba oxide firimu pachigadzirwa chearuminiyamu (anode) nekuda kwekuita kwemagetsi emagetsi anoiswa mune inoenderana electrolyte uye chaiyo maitiro mamiriro.

2.Kuputika kwejecha

Sandblasting kazhinji inzira yepakati yekurapa kwepamusoro kwearuminiyamu stamping zvikamu. Mushure mekunge aluminium stamping zvikamu zvaputirwa nejecha, maburrs epamusoro uye mavara emafuta anogona kubviswa zvinobudirira. Inogona kuvandudza kuchena kwepamusoro kwealuminium stamping zvikamu. Nekudzora zvinhu zvinoputika, nzvimbo dzakasiyana dzinogona kuwanikwa uye kushata kwechigadzirwa kunogona kuwedzerwa. Kuita kwechigadzirwa kunogona kuvandudzwa zvakanyanya. Muchiitiko chinotevera chekurapa kwepamusoro, iyo yekunamatira pakati pearuminiyamu stamping zvikamu uye coating inogona zvakare kuwedzerwa zvakanyanya, zvichiita kuti chigadzirwa chiwedzere kusimba uye chakanaka.

3. Kuchenesa kurapwa

Iyo yakakwenenzverwa aluminium stamping zvikamu zvinogona kuva padyo negirazi mhedzisiro, iyo inovandudza zvakanyanya giredhi uye aesthetics yechigadzirwa. Nekudaro, nekuda kwehunhu hwezvigadzirwa zvealuminium, zvitambi zvealuminium zvinoda kupenya kushoma. Kana pasina kumwe kurapwa kwepamusoro kunoitwa mushure mekupenya, kusimba kwechigadzirwa kunokanganiswa. Uyezve, mushure mealuminium stamping zvikamu zvakakwenenzverwa, zvakaoma kuchengetedza girazi mhedzisiro kwenguva yakareba. Naizvozvo, kana girazi mhedzisiro inodiwa, inokurudzirwa kushandisasimbi isina ngurasechinhu chigadzirwa.

4. Kudhirowa kwewaya

Kune akawanda marudzi emabrashi ealuminium stamping, anonyanya kuzivikanwa kudhirowa kwakatwasuka, chaotic kudhirowa, spiral kudhirowa uye shinda yekudhirowa. Mushure mekunge zvikamu zvealuminium zvidhindo zvadhirowa waya, mavara akajeka uye akapfava anogona kuonekwa pamusoro, uye chigadzirwa chinopa vanhu ruzivo rwekuona kwemaitiro esirika anopenya.

Aluminium stamping zvikamu zvinongoda kurapwa kwepamusoro mushure mekugadzirisa, asi nzira yekurapa inosarudzwa zvinoenderana nezvinodiwa nemutengi. Mukushaikwa kwekukumbira kwevatengi, anodizing inowanzove yakasarudzika.

Sei kusarudza Xinzhe kuti tsika simbi stamping zvikamu?

Xinzhe inyanzvi yekutsikisa simbi yaunoshanyira. Kushandira vatengi pasi rese, tanga tichinyanya hunyanzvi hwekutsikisa simbi kweanoda kusvika makore gumi. Vedu vane tarenda rakatanhamara mold matekiniki uye mainjiniya edhizaini vakazvipira, nyanzvi, uye vane hunyanzvi hwekushanda.

Chii chinokosha pane zvatinokwanisa kuita? Imwe temu inopfupisa mhinduro: simbisiro yemhando uye specs. Kwatiri, purojekiti imwe neimwe yakasiyana. Tinosundwa nechiratidzo chenyu, uye ibasa redu kuti chiono ichocho chiitike. Tinoedza kunzwisisa chikamu chese chepurojekiti yako kuti tiite izvi.

Isu tinoisa simba rakawanda mukuona chiono chako kana tave nekuchibata. Munzira, pane nzvimbo dzakawanda dzekutarisa. Izvi zvinoita kuti tive nechokwadi chekuti chigadzirwa chakapedzwa chinogutsa zvizere zvaunoda.

Boka redu parizvino rinotarisana nekupa tsika simbi stamping masevhisi mundima dzinotevera:

Kudhinda mumatanho kune zvese zvidiki uye hombe huwandu

Secondary stamping muzvidimbu zvidiki

kubata mukati me mold

Taping yechipiri kana gungano

Machining uye kuumba

Kana uchida rumwe ruzivo, usazeza kutibata nesu.