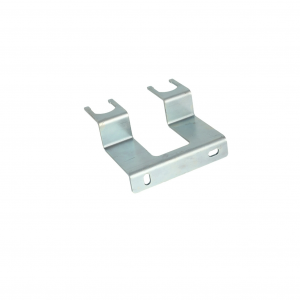

Tsika yemotokari simbi yekutsikisa chigadzirwa Stamping Bending Zvikamu

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Metal stamping zvinhu

Xinzhe inopa zvinotevera zvigadzirwa kune edu ese akajairwa uye tsika simbi stamping:

Simbi: CRS simbi se1008, 1010, kana 1018 yakakurumbira; general-chinangwa zvinhu zvakakwana kutonhora kuumba.

Stainless Simbi: yakadai se301, 304, uye 316/316L. 301 Stainless simbi ine yakanakisa tensile simba, nepo 304 ine yakawedzera kukosha kuita uye kushora kuramba patembiricha yepamusoro. 316/316L simbi inoratidzira yakanakisa corrosion resistance yevatatu, kunyangwe ichidhurawo zvakawanda.

Mhangura: inosanganisira C110, inova kondakita ane simba uye inoumbwa nyore.

Brass: ndarira 230 (85/15) uye 260 (70/30) inoumbwa zvakanyanya uye isingadziviriri. Aya maalloys endarira anozivikanwawo sendarira tsvuku uye yero yendarira, zvichiteerana.

Xinzhe inogona kudhinda mamwe pepa simbi zvinhu pakukumbira, saka inzwa wakasununguka kubata nyanzvi dzedu nezvezvinhu zvaunoda.

Zvinhu zvedu zvekutsikisa zvinogona kugadziridzwa nekuputika bhedhi, poda coating, chem firimu, anodizing, uye plating mugoridhe, sirivheri, kana electroless nickel.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Metal stamping inzira yekugadzira umo macoils kana mashizha akafuratira emidziyo anoumbwa kuita chaiwo maumbirwo. Kutsika kunosanganisira akawanda ekugadzira matekiniki akadai sekuvhara, kubaya, embossing, uye inofambira mberi kufa stamping, kutaura mashoma. Zvikamu zvinoshandisa musanganiswa weaya matekiniki kana zvakazvimirira, zvichienderana nekuoma kwechidimbu. Mukuita izvi, makoiri asina chinhu kana mashizha anodyiswa mumuchina wekutsikisa unoshandisa maturusi uye unofa kugadzira maficha uye nzvimbo musimbi. Metal stamping inzira yakanakisa yekugadzira-misa-akasiyana mativi akaomarara, kubva pamagonhi emotokari mapaneru uye magiya kusvika kune madiki emagetsi anoshandiswa mumafoni nemakomputa. Matampu maitiro anogamuchirwa zvakanyanya mumotokari, maindasitiri, mwenje, zvekurapa, uye mamwe maindasitiri.

Sei kusarudza Xinzhe kuti tsika simbi stamping zvikamu?

Paunouya kuXinzhe, unouya kune nyanzvi yekutsikisa simbi. Isu takatarisa pane simbi stamping kwemakore anopfuura 10, kushandira vatengi kubva pasirese. Vagadziri vedu vane hunyanzvi hwekugadzira mainjiniya uye mold matekiniki vane hunyanzvi uye vakazvipira.

Chii chinoita kuti tibudirire? Mhinduro yacho mazwi maviri: zvirevo uye vimbiso yemhando. Yese chirongwa chakasiyana kwatiri. Chiono chako chinokupa simba, uye ibasa redu kuita kuti chiratidzo ichocho chive chokwadi. Isu tinoita izvi nekuyedza kunzwisisa zvese zvidiki zvepurojekiti yako.

Kana taziva zano rako, tichashanda pakurigadzira. Kune akawanda ekutarisa mukati mekuita. Izvi zvinotibvumira kuve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa zvako zvakakwana.

Parizvino, timu yedu inoita zvetsika simbi stamping masevhisi munzvimbo dzinotevera:

Progressive stamping yemabhechi madiki nemahombe

Diki batch yechipiri stamping

In-mold tapping

Secondary/assembly tapping

Kugadzira uye kugadzira