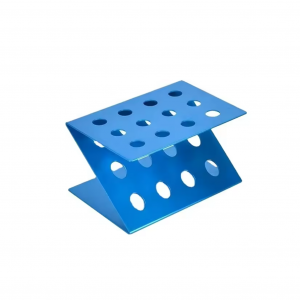

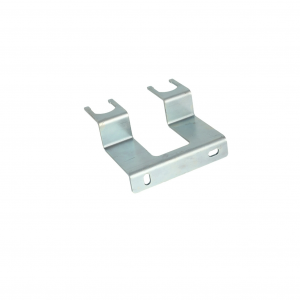

precision inotonhora stamping process supplier

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. Kupfuura makore gumiyehunyanzvi hwekutengeserana mhiri kwemakungwa.

2. Ipaone-stop servicekubva pakugadzira mold kusvika kune chigadzirwa.

3. Kurumidza kuburitsa nguva, nezve30-40 mazuva. In stock mukati mevhiki imwe.

4. Yakasimba yemhando yekutonga uye maitiro ekugadzirisa (ISOcertified mugadziri uye fekitori).

5. Mimwe mitengo inonzwisisika.

6. Nyanzvi, fekitari yedu inekupfuura 10makore enhoroondo mumunda wesimbi stamping sheet simbi.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Stamping basics

Kutsika (kunonziwo kudzvanya) kunosanganisira kuisa simbi yakati sandara mucoil kana fomu isina chinhu mumuchina wekutsikisa. Muchidhina, chishandiso uye nzvimbo dzekufa zvinogadzira simbi kuita chimiro chaunoda. Kurova, kuvhara, kukotama, kutsika, embossing uye flanging ese ndiwo maitiro ekutsikisa anoshandiswa kugadzira simbi.

Zvinhu zvisati zvagadzirwa, nyanzvi dzekutsika dzinofanirwa kugadzira mold kuburikidza neCAD/CAM engineering. Aya madhizaini anofanirwa kuve akajeka sezvinobvira kuti ave nechokwadi chekubvumidzwa kwakakodzera kune yega punch uye kubhenda kune yakakwana chikamu chemhando. Chishandiso chimwe chete 3D modhi inogona kuve nemazana ezvikamu, saka maitiro ekugadzira anowanzo kuoma uye anopedza nguva.

Kana dhizaini yatemwa, vagadziri vanogona kushandisa akasiyana machining, kugaya, kucheka waya, uye mamwe masevhisi ekugadzira kupedzisa kugadzira kwayo.

Metal stamping dhizaini maitiro

Metal stamping inzira yakaoma iyo inogona kusanganisira dzakasiyana siyana dzekugadzira simbi - blanking, punching, kukotama uye kubaya, pakati pezvimwe.

Blanking: Maitiro aya anosanganisira kucheka rough outline kana chimiro chechigadzirwa. Chinangwa chechinhanho ichi ndechekudzikisa uye kudzivirira maburrs, ayo anogona kuwedzera mutengo wechikamu uye kuwedzera nguva yekuendesa. Danho iri nderokuona dhayamita yegomba, geometry/taper, kumucheto kuenda kumaburi spacing uye pekuisa punch yekutanga.

Kupeta: Paunogadzira mabhenji muzvikamu zvesimbi zvakadhindwa, zvakakosha kuti usiye zvinhu zvakaringana parutivi - ita shuwa kuti wagadzira chikamu uye chisina chinhu kuitira kuti pave nezvakakwana kuita bend.

Kurovera: Uku kuvhiya ndipo panotepwa mipendero yesimbi yakadhindwa kuti ipwanye kana kutyora pfuti; izvi zvinogadzira mipendero yakapfava munzvimbo dzakakandwa dzechikamu chegeometry; izvi zvinowedzerawo simba rakawedzerwa kune nzvimbo dzenzvimbo dzechikamu, uye Inogona kushandiswa kudzivirira yechipiri kugadzirisa senge deburring uye kugaya.