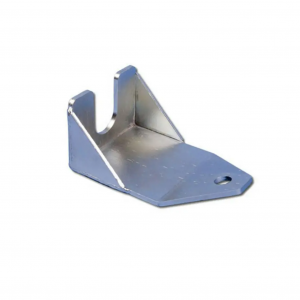

Tsika simbi yakadhindwa Zvikamu Zvikamu zveTractor

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Quality system

Zvese zvivakwa zvedu ndezve ISO 9001 certified. Uye zvakare, Xinzhe ane ruzivo rwakakura mumhando yekudzora masisitimu uye maitirwo mumaindasitiri mazhinji uye chaiwo maapplication.

Kugadzira Zvikamu Kubvumidzwa Maitiro

Kudzora Chirongwa

Kukundikana Mode uye Effects Analysis (FMEA)

Measurement Systems Analysis (MSA)

dzidziso yekutanga

Statistical Process Control (SPC)

Yedu yemhando marabhoritari inovakawo macalibration masisitimu kubva kuCMM uye optical comparator kusvika pakuomarara kuyedzwa. Bata nesu kuti udzidze zvakawanda.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Sei kusarudza xinzhe?

Paunouya kuXinzhe, unouya kune nyanzvi yekutsikisa simbi. Isu takatarisa pane simbi stamping kwemakore anopfuura 10, kushandira vatengi kubva pasirese. Vagadziri vedu vane hunyanzvi hwekugadzira mainjiniya uye mold matekiniki vane hunyanzvi uye vakazvipira.

Chii chinoita kuti tibudirire? Mhinduro yacho mazwi maviri: zvirevo uye vimbiso yemhando. Yese chirongwa chakasiyana kwatiri. Chiono chako chinokupa simba, uye ibasa redu kuita kuti chiratidzo ichocho chive chokwadi. Isu tinoita izvi nekuyedza kunzwisisa zvese zvidiki zvepurojekiti yako.

Kana taziva zano rako, tichashanda pakurigadzira. Kune akawanda ekutarisa mukati mekuita. Izvi zvinotibvumira kuve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa zvako zvakakwana.

Parizvino, timu yedu inoita zvetsika simbi stamping masevhisi munzvimbo dzinotevera:

Progressive stamping yemabhechi madiki nemahombe.

Diki batch yechipiri stamping.

In-mold tapping.

Secondary/assembly tapping.

Kugadzira uye kugadzira.

BASA REDU

1. Professional R&D timu - Mainjiniya edu anopa akasiyana magadzirirwo ezvigadzirwa zvako kutsigira bhizinesi rako.

2. Quality Supervision Team - Zvose zvinogadzirwa zvinoongororwa zvakasimba zvisati zvatumirwa kuti zvive nechokwadi chokuti zvigadzirwa zvose zvinofamba zvakanaka.

3. Inoshanda Logistics timu - customized kurongedza uye nenguva yekutevera inovimbisa kuchengetedzwa kusvika wagamuchira chigadzirwa.

4. Yakazvimirira mushure mekutengesa timu-inopa panguva yehunyanzvi masevhisi kune vatengi maawa makumi maviri nemana pazuva.

5. Professional sales team - iyo yakanyanya hunyanzvi ruzivo ichagoverwa newe kuti ikubatsire kuita bhizinesi zviri nani nevatengi.