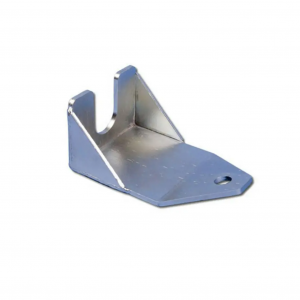

Tsika Perforating Bend Stamping Component Chikamu Galvanized Sheet Metal

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Galvanizing process types

1. Cyanide galvanizing: Zvisinei nekurambidzwa nekuda kwekunetsekana kwezvakatipoteredza, cyanide galvanizing ine mashandisiro akati wandei. Hunhu hwechigadzirwa hwakanaka kana uchishandisa yakaderera cyanide (micro cyanide) plating mhinduro, uye inonyanya kukodzera kune ruvara galvanizing.

2. Zincate galvanizing: Nzira iyi yakagadzirwa kubva mucyanide galvanizing uye yakakamurwa kuva mapoka makuru maviri: Radio neTerevhizheni Institute's "DE" series uye Wuhan Material Protection Institute's "DPE" series. Iyo yekuputira lattice chimiro chakakodzera kune ruvara galvanizing, ine yakanaka corrosion resistance, uye iri columnar.

3. Chloride galvanizing: kusvika ku40% ye electroplating sector inoshandisa izvi zvakanyanya. Yakanakira sirivheri kana yebhuruu chena passivation, uye kunyanya inokodzera kurapwa kwepamusoro kunotevera kushandiswa kwevarnish inonyungudika nemvura.

4. Sulfate galvanizing inodhura uye yakakodzera kuenderera mberi kwesimbi yewaya, mitsetse, nezvimwe zvinhu zviri nyore, zvakakora, uye zvakakura.

5. Kupisa-dip galvanizing: Kuti uone kuti mvura yezinki inonamatira kune zvikamu zvakaputirwa zvakafanana uye zvakanyanyisa, tora zvikamu kutanga kubvisa oxide layer. Zvadaro, vanyudze mumvura yezinki mutangi rinopisa-dip plating.

6. Electro-galvanizing: The plated components 'surface inocheneswa kubvisa tsvina, pickled, uye oiri neguruva zvinobviswa zvisati zvanyudzwa muzinc munyu. Zvikamu zvakaputirwa zvakafukidzwa mune zinc layer yekutenda kune electrolytic reaction.

7. Mechanical galvanizing: Kuputira kunogadzirwa nemagetsi kurovera uye makemikari adsorbing zinc powder kune zvikamu zvakaputirwa.

8. Yakanyungudutswa galvanizing: Simbi yakaputirwa nedandemutande rezinc yakanyungudutswa nekuinyudza mukunyunguduka kwealuminium alloy, iyo inowedzera kupfeka uye kusagadzikana kwemarara.

Ese maitiro ambotaurwa ane mabhenefiti uye anokanganisa ezvawo, uye akakodzera kune mamwe mamiriro ekushandisa uye zvinodiwa.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Kupisa dip galvanizing process

Galvanizing inzira yekurapa pamusoro inoshandiswa kudzivirira kukoromoka uye kuwedzera aesthetic kukwezva nekuisa zinc layer pamusoro pesimbi, alloys, uye zvimwe zvinhu. Kupisa dip galvanizing ndiyo nzira huru.

Zinc inonzi isimbi amphoteric sezvo inonyungudika zviri nyore muasidhi uye alkalis. Mhepo yakaoma inokonzera shanduko shoma mu zinc. Pamusoro pezinc, hutete hwezinc carbonate hunokura mumhepo ine hunyoro. Zinc ine yakaderera corrosion resistance mu sulfur dioxide, hydrogen sulfide, uye marine atmospheres. Iyo zinc coating inonyungudika nyore, kunyanya munzvimbo dzine tembiricha yakakwira, humidity yakakwira, uye organic acids.

Zinc ine yakajairika electrode simba -0.76 V. Zinc coating is anodic coating for simbi substrates. Chinangwa chayo chikuru ndechekumisa simbi kubva pakuora. Kugona kwayo kudzivirira kunoenderana zvakananga nehukobvu hwekuputira. Iyo zinc yekushongedza yekushongedza uye inodzivirira hunhu inogona kukwidziridzwa zvakanyanya nekupfuura, kufa, kana kuisa gloss inodzivirira coating.

FAQ

Mubvunzo: Iwe uri kambani yekutengesa kana mugadziri?

A: Isu tiri mugadziri.

Q: Nzira yekuwana sei quote?

A: Ndapota tumira mifananidzo yako (PDF, stp, igs, nhanho ...) kwatiri ne email , uye utiudze zvinhu, kurapwa kwepamusoro uye huwandu, ipapo tichakuitira quotation.

Mubvunzo: Ndinogona kuodha chete 1 kana 2 pcs yekuyedza?

A: Hongu, hongu.

Q. Unogona kubudisa maererano sampuli?

A: Hongu, tinogona kugadzira nemasampuli ako.

Mubvunzo: Yakareba sei nguva yako yekuendesa?

A: 7 ~ 15 mazuva, zvinoenderana nekurongeka kwehuwandu uye maitiro echigadzirwa.

Q. Unoedza zvinhu zvako zvose usati wasununguka here?

A: Hongu, tine 100% bvunzo tisati tasvika.

Mubvunzo: Iwe unoita sei bhizinesi redu kwenguva refu uye hukama hwakanaka?

A:1. Isu tinochengeta mhando yakanaka uye mutengo wemakwikwi kuti tive nechokwadi chekuti vatengi vedu vanobatsirwa;

2. Tinoremekedza mutengi wese seshamwari yedu uye tinoita bhizinesi nemwoyo wose uye tinoita shamwari navo, pasinei nokuti vanobva kupi.