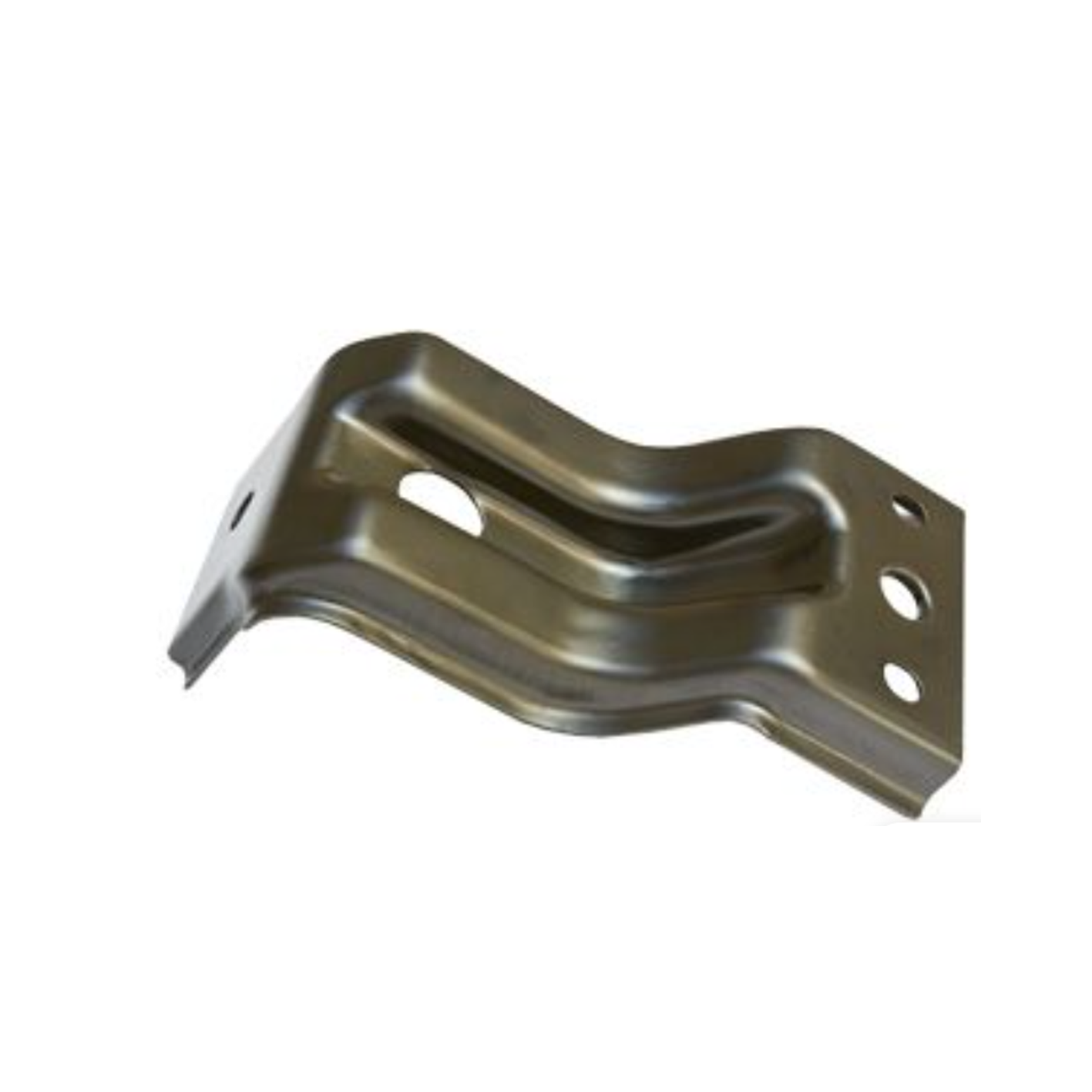

Yakagadzirirwa aluminium alloy sheet simbi inokotama zvigadzirwa

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. Kupfuura makore gumiyehunyanzvi hwekutengeserana mhiri kwemakungwa.

2. Ipaone-stop servicekubva pakugadzira mold kusvika kune chigadzirwa.

3. Kurumidza kuburitsa nguva, nezve30-40 mazuva. In stock mukati mevhiki imwe.

4. Yakasimba yemhando yekutonga uye maitiro ekugadzirisa (ISOcertified mugadziri uye fekitori).

5. Mimwe mitengo inonzwisisika.

6. Nyanzvi, fekitari yedu inekupfuura 10makore enhoroondo mumunda wesimbi stamping sheet simbi.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Nhanganyaya kune zvigadzirwa zveelevator

Zvishandiso zvesimbi zvinowanzoshandiswa muzvikwiridzo zvinonyanya zvinosanganisira simbi isina tsvina, alloy structural simbi, kabhoni structural simbi, aruminiyamu alloy, mhangura, inotonhorera-inodhonzwa profiles, inopisa-yakakungurutswa profiles, etc. Zvinotevera nhanganyaya.

Simbi isina simbi: Inodzivirira kuita ngura, haipfeki uye iri nyore kuchenesa. Inowanzoshandiswa mumashizha emusuwo weelevator, mashizha emasuo emasuo uye zvimwe zvikamu.

Alloy structural simbi uye kabhoni structural simbi: Iwo ane yakakwirira simba uye kuoma uye anoshandiswa kutsungirira mutoro wezvikwiriso. Inowanzo shandiswa mumafuremu emasuo emasuo, mapuranga emasuo uye zvimwe zvikamu.

Aluminium alloy ine huremu huremu, kusimba kwepamusoro uye yakanaka purasitiki, uye inoshandiswa mukusimudza sirin'i uye mapaneru emadziro.

Mhangura: Inoshandiswa mumatunhu uye conductive zvikamu zvemaelevator uye ine maitiro e-anti-oxidation, ruzha uye kupisa conduction.

Cold-drawn profiles uye inopisa-yakatenderedzwa profiles: Ane simba rakawanda, kupfeka kuramba, kuramba deformation, kusimba kwepamusoro uye kuoma zvakateerana, uye anoshandiswa mukugadzira njanji yeelevator.

Kushandiswa kwezvinhu zvakasiyana-siyana zvesimbi kuchasiyana zvichienderana nechinangwa, modhi uye mhando yeelevator. Paunosarudza zvigadzirwa zvesimbi zvakakodzera, unofanirwa kufunga nezve kuchengetedzwa kwekuita kweelevator.

Sei kusarudza isu

1.Nyanzvi yekugadzira simbi yesimbi uye simbi stamping zvikamu kweanopfuura makore gumi.

2. Chiyero chepamusoro chekugadzirwa ndicho chinhu chatinotarisa zvakanyanya.

3. Rutsigiro rwakatanhamara runowanikwa kutenderedza-wachi.

4. Mukati memwedzi, kusununguka kunoitika nokukurumidza.

5. Chikwata chakasimba chehunyanzvi chinotsigira uye chinotsigira tsvakiridzo nebudiriro.

6. Kurudzira kubatana kweOEM.

Tinogashira mashoko akanaka kubva kuvatengi vedu uye zvichemo zvishoma.

8. Chigadzirwa chega chega chine zvinhu zvakanaka zvemuchina uye hupenyu hwakanaka.

9. Mutengo wemakwikwi wakakodzera.