Customized precision motokari simbi inokotama zvikamu

Tsanangudzo

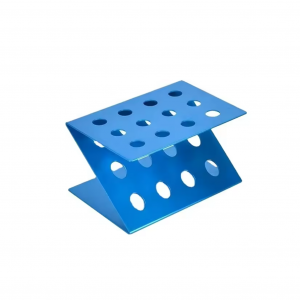

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Bending musimboti

Nheyo yekukotamisa simbi inonyanya kusanganisa deformation yepurasitiki yezvinhu zvesimbi pasi pekuita kwemasimba ekunze. Izvi zvinotevera sumo yakadzama:

Panguva yekukotama, simbi pepa rinotanga rapinda elastic deformation rozopinda mupurasitiki deformation. Muchikamu chekutanga chekukotama kwepurasitiki, pepa rinokotama zvakasununguka. Sezvo kudzvinyirirwa kunoitwa neforoma pandiro kunowedzera, kusangana pakati peplate uye mold zvishoma nezvishoma inoswedera pedyo, uye radius ye curvature uye kukotama nguva ruoko runodzikira.

Munguva yekukotama maitiro, nzvimbo yekushushikana inopinda elastic deformation, nepo deformation yepurasitiki inoitika pamativi ese ekukotama, zvichikonzera shanduko yedimensional mune simbi zvinhu.

Kuti udzivise kutsemuka, deformation uye mamwe matambudziko panzvimbo yekukotama, zvigadziriso zvinowanzoitwa nekuwedzera kubhenda radius, kukotama kakawanda, nezvimwe.

Iyi nheyo haishande chete pakukotama kwemidziyo yakatsetseka, asiwo pakukotama kwepombi dzesimbi, senge mu hydraulic pombi yekubhenda muchina uko kudzvanywa kunogadzirwa ne hydraulic system kunoshandiswa kugadzira pombi. Kazhinji, kubhenda kwesimbi inzira yekugadzira iyo inoshandisa deformation yepurasitiki yesimbi kugadzira zvikamu kana zvikamu zvechimiro chinodiwa uye saizi.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

kusarudzwa kwezvinhu

Zvinhu zvakasiyana-siyana zvakakodzerwa nenzira dzakasiyana dzekukotama. Kusarudzwa kwezvinhu kunoda kuenderana nezvinodiwa zvechigadzirwa uye zvinodiwa pakugadzirisa. Kazhinji, zvinhu zvine hutano hwakanaka uye yakagadzikana kugadzirisa kushanda zvinoda kusarudzwa.

1. Simbi yesimbi: Inokodzera zvikamu zvine makona madiki ekukotama, maumbirwo akareruka uye pasi-chaiyo zvinodiwa, senge mabhodhi ekuratidzira, makabati, masherufu uye imwe fenicha.

2. Aluminium: Iine zvakanakira uremu huremu, kusimba kwepamusoro, kushomeka kwekudzivirira uye conductivity. Inokodzera zvikamu zvinoda kurongeka kwepamusoro uye makona mahombe, senge chassis, mafuremu, zvikamu, nezvimwe.

3. Stainless simbi: Iine yakanakisa corrosion resistance, high simba, good toughness uye humwe hunhu, asi zvakaoma kugadzirisa. Inokodzera zvikamu zvinoda kunyatsojeka, senge indasitiri yemakemikari, michina yekurapa, nezvimwe.

Sei kusarudza Xinzhe kuti tsika simbi stamping zvikamu?

Paunouya kuXinzhe, unouya kune nyanzvi yekutsikisa simbi. Isu takatarisa pane simbi stamping kwemakore anopfuura 10, kushandira vatengi kubva pasirese. Vagadziri vedu vane hunyanzvi hwekugadzira mainjiniya uye mold matekiniki vane hunyanzvi uye vakazvipira.

Chii chinoita kuti tibudirire? Mhinduro yacho mazwi maviri: zvirevo uye vimbiso yemhando. Yese chirongwa chakasiyana kwatiri. Chiono chako chinokupa simba, uye ibasa redu kuita kuti chiratidzo ichocho chive chokwadi. Isu tinoita izvi nekuyedza kunzwisisa zvese zvidiki zvepurojekiti yako.

Kana taziva zano rako, tichashanda pakurigadzira. Kune akawanda ekutarisa mukati mekuita. Izvi zvinotibvumira kuve nechokwadi chekuti chigadzirwa chekupedzisira chinosangana nezvinodiwa zvako zvakakwana.

Parizvino, timu yedu inoita zvetsika simbi stamping masevhisi munzvimbo dzinotevera:

Progressive stamping yemabhechi madiki nemahombe

Diki batch yechipiri stamping

In-mold tapping

Secondary/assembly tapping

Kugadzira uye kugadzira