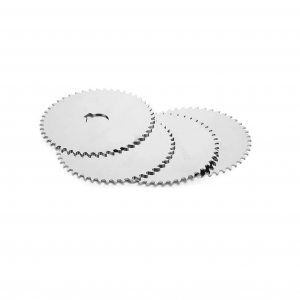

Customized Stainless simbi bracket sheet simbi inokotama zvikamu

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Minda inoshanda

Sheet simbi yekubhenda zvikamu zvinoshandiswa zvakanyanya muminda yakawanda. Aya anotevera mamwe makuru ekushandisa minda:

1. Indasitiri yemotokari: Sheet metal bending processing inoshandiswa zvakanyanya mumotokari yemotokari uye inoshandiswa kugadzira zvikamu zvemuviri, magonhi, hoods, etc. Kuburikidza nepepa resimbi bending processing, mashizha esimbi anogona kugadziriswa muzvikamu zvemuviri ane simba rakanaka uye kuoma, zvichiita kuti kugadzikana kwemotokari.

2. Indasitiri yekugadzira uye yekushongedza: Sheet metal bending processing inoshandiswawo zvakanyanya mukugadzira zvinhu zvekuvaka uye zvekushongedza. Semuenzaniso: kugadzira matenga esimbi, facade mapaneru, sirin'i uye zvimwe zvekuvaka. Zvinhu izvi zvine simba rakasimba uye zvisingapindi mvura, zvinogona kushandiswa mumamiriro ezvinhu akasiyana-siyana ezvakatipoteredza, uye zvinogona kudzivirira zvivakwa kubva pakukuvadzwa kubva kunze kwezvinhu.

3. Kugadzira fenicha: Mukugadzira fenicha, inoshandiswa kugadzira akasiyana simbi fenicha zvikamu, semakumbo etafura, zvigaro zvechigaro, nezvimwe.

4. Aerospace: Mumunda wemuchadenga, inoshandiswa kugadzira zvikamu zvezvimiro zvendege uye spacecraft, semapapiro, fuselage, nezvimwe.

5. Indasitiri yemagetsi: Muindasitiri yemagetsi, inoshandiswa kugadzira dzimba, mabhuraketi uye zvimwe zvikamu zve solar panel uye mhepo midziyo yemagetsi.

6. Sheet simbi yekubhenda zvikamu zvinogonawo kushandiswa mumashaft erevheta. Mumashaft erevheta, simbi yesimbi inokotama zvikamu zvinogona kushandiswa kugadzira zvimiro zvesimbi, izvo zvine zvakanakira kusimba kwakasimba kutakura uye kwakanaka kuramba kudengenyeka. Sezvo sheet simbi kubhenda ichikwanisa kugadzira simbi machira kuita zvikamu zvezvimiro zvine simba rakanaka uye kuomarara, inokodzera nguva dzakadai semashaft erevheta anoda kutakura mitoro inorema uye ane zvimwe zvinodiwa kudzivirira kudengenyeka.

Pamusoro pezvo, pepa simbi yekubhenda kugadzirisa inogonawo kuita mhando dzakasiyana dzekupeta sezvinodiwa, senge V-yakaita kupeta uye U-yakaita kupeta, kusangana nezvinodiwa zvemaumbirwo akasiyana uye saizi. Naizvozvo, mumashafu ekusimudza, simbi yesimbi inokotama zvikamu zvinogona kushandiswa zvakanyanya kugadzira zvakasiyana-siyana zvimiro, senge.kutsigira mafuremu, matanda, makoramu, nezvimwewo, kuve nechokwadi kugadzikana uye kuchengetedzeka kweshaft yeelevator.

Sheet simbi inokotama zvikamu zvinoita basa rakakosha muminda iyi, ichipa rutsigiro uye vimbiso yekugadzira nekusimudzira maindasitiri akasiyana.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Quality waranti

1. Zvese zvigadzirwa zvekugadzira uye kuongorora zvine marekodhi emhando uye data yekuongorora.

2. Zvikamu zvose zvakagadzirirwa zvinoedzwa zvakasimba zvisati zvatumirwa kune vatengi vedu.

3. Kana chimwe chezvikamu izvi chakakuvadzwa pasi pemamiriro ekushanda akajairika, tinovimbisa kuvatsiva imwe neimwe pasina.

Ndicho chikonzero nei tine chivimbo chekuti chero chikamu chatinopa chichaita basa uye chiuye newaranti yehupenyu hwese kubva kune hurema.

FAQ

Mubvunzo: Iwe uri kambani yekutengesa kana mugadziri?

A: Isu tiri mugadziri.

Q: Nzira yekuwana sei quote?

A: Ndapota tumira mifananidzo yako (PDF, stp, igs, nhanho ...) kwatiri ne email , uye utiudze zvinhu, kurapwa kwepamusoro uye huwandu, ipapo tichakuitira quotation.

Mubvunzo: Ndinogona kuodha chete 1 kana 2 pcs yekuyedza?

A: Hongu, hongu.

Q. Unogona kubudisa maererano sampuli?

A: Hongu, tinogona kugadzira nemasampuli ako.

Mubvunzo: Yakareba sei nguva yako yekuendesa?

A: 7 ~ 15 mazuva, zvinoenderana nekurongeka kwehuwandu uye maitiro echigadzirwa.

Q. Unoedza zvinhu zvako zvose usati wasununguka here?

A: Hongu, tine 100% bvunzo tisati tasvika.

Mubvunzo: Iwe unoita sei bhizinesi redu kwenguva refu uye hukama hwakanaka?

A:1. Isu tinochengeta mhando yakanaka uye mutengo wemakwikwi kuti tive nechokwadi chekuti vatengi vedu vanobatsirwa;

2. Tinoremekedza mutengi wese seshamwari yedu uye tinoita bhizinesi nemwoyo wose uye tinoita shamwari navo, pasinei nokuti vanobva kupi.