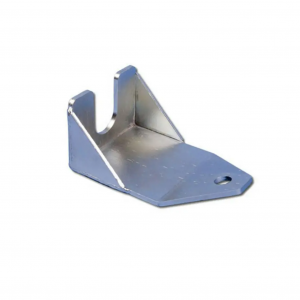

Elevator mudziyo wegonhi musoro unoisa bracket erevheta accessories

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. Anopfuura makore gumi eruzivo mukutengeserana nedzimwe nyika.

2. Ipa imwe-stop shopu yezvese kubva kune chigadzirwa kuendesa kune mold design.

3. Kukurumidza kutumira, kutora pakati pe30 ne40 mazuva. mukati mevhiki.

4. Yakasimba maitiro ekutonga uye kunaka manejimendi (mugadziri uye fekitori ine ISO certification).

5. Zvimwe zvinokwanisika mari.

6. Unyanzvi: Neanopfuura makore gumi echiitiko, chirimwa chedu chave chidhinda simbi pepa.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Metal stamping process inzira yakakosha yesimbi yekugadzirisa uye inoshandiswa zvakanyanya munzvimbo dzakasiyana dzekugadzira:

1. Tsanangudzo uye musimboti: Metal stamping process inzira yekugadzira iyo inoshandisa kumanikidza kukanganisa simbi mapepa muforoma. Nheyo yakakosha ndeyekushandisa zvibhakera uye kufa kuita kumanikidza pamarata esimbi kukonzera deformation yepurasitiki, nekudaro kuwana simbi zvidimbu zvine chimiro chinodiwa, saizi uye kuita.

2. Mold design: Mold chikamu chinokosha chesimbi yekutsika, uye dhizaini yayo inobata zvakananga chigadzirwa chemhando uye kubudirira kwekugadzira. Mold dhizaini inoda kufunga nezve chimiro, saizi, kurongeka kwezvinodiwa zvechigadzirwa, pamwe nekuita uye deformation mitemo yechinhu.

3. Midziyo yekutsikisa uye sarudzo: Midziyo yekutsikirira inonyanya kusanganisira zvibhakera, zvitsigiro, hydraulic presses, etc. Kusarudza midziyo yekutsikisa yakakodzera kunoda kutariswa kwakadzama kwakavakirwa pazvinhu zvakaita sehukuru hwechigadzirwa, ukobvu, zvinhu, uye batch yekugadzira.

4. Stamping process uye classification: Metal stamping process inowanzobatanidza kuvhara, kurova, kukotama, kudhirowa kwakadzika, kutema uye mamwe maitiro. Zvichienderana nezvakasiyana zvechigadzirwa zvinodiwa uye zvinhu zvemukati, akasiyana stamping process musanganiswa anogona kusarudzwa.

5. Maitiro ekugadzirisa uye optimization: Maitiro ekugadzirisa anosanganisira kukurumidza kutsika, kudzvanywa, tembiricha, etc. Kusarudzwa uye optimization yezviyero izvi zvakakosha zvikuru pakuvandudza kunaka kwechigadzirwa, kuderedza kushandiswa kwesimba nekuvandudza kugona kwekugadzira.

6. Kukanganisa kwakajairika uye zvigadziriso: Munguva yesimbi stamping process, zvimwe zvinowanzoitika zvikanganiso zvinogona kuitika, senge kuputsa, kusaenzana kwepurasitiki deformation, wrinkles, burrs, etc. Kuti ugadzirise zvikanganiso izvi, zvinogadzirisa zvinogadzirisa zvinoda kutorwa, senge optimizing mold design, kugadzirisa maitiro parameters, kuvandudza zvinhu zvemhando, nezvimwe.

7. Mamiriro ekushandisa: Metal stamping tekinoroji inoshandiswa zvakanyanya mumotokari, zvemagetsi, midziyo yemumba, aerospace uye mamwe minda. Inogona kuburitsa simbi zvikamu zvakasiyana-siyana uye saizi kuti isangane nezvinodiwa zvemaindasitiri akasiyana.

Metal stamping process ndiyo yakakosha simbi yekugadzirisa nzira ine yakafara application tarisiro. Nekuramba uchikwenenzvera dhizaini yekuumbwa, maparamendi ekugadzirisa uye maitiro ekugadzira, mhando yechigadzirwa inogona kuvandudzwa, mutengo wekugadzira wakaderedzwa, uye shanduko yemusika zvinodiwa zvinosangana.

FAQ

1.Q: Ndeipi nzira yekubhadhara?

A: Tinobvuma TT (Bank Transfer), L/C.

(1. Pamari yese iri pasi peUS$3000, 100% pachine nguva.)

(2. Pamari yese iri pamusoro peUS$3000, 30% pachine nguva, imwe yacho ichipesana negwaro rekopi.)

2.Q: Fekitari yako iri kupi?

A: Fekitari yedu iri muNingbo, Zhejiang.

3.Q: Iwe unopa emahara samples?

A: Kazhinji isu hatipe emahara samples. Pane semuenzaniso mutengo unogona kudzoserwa mushure mekunge waisa odha.

4.Q: Chii chaunowanzo tumira kuburikidza?

A: Kutakura nemhepo, Kutakura kwegungwa, kutaura ndiyo yakanyanya nzira yekutakura nekuda kwehuremu hudiki uye saizi yezvigadzirwa chaizvo.

5.Q: Ini handina dhirowa kana mufananidzo unowanikwa kune zvigadzirwa zvetsika, unogona kuzvigadzira here?

A: Ehe, tinogona kugadzira yakanakisa dhizaini inoenderana nekushandisa kwako.