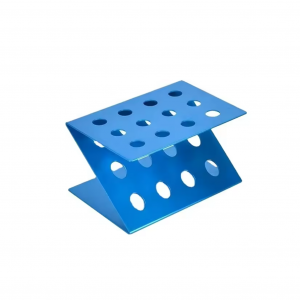

Metal Steel Elevator Bracket Galvanized Stamping Mounting Bracket

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Basa rekutsva galvanizing

Mabasa esimbi galvanizing anonyanya kusanganisira zvinotevera pfungwa:

Inodzivirira kubva mukuora uye ngura. Iyo galvanized layer inokwanisa kuparadzanisa simbi kubva pakubata nemhepo, unyoro uye zvimwe zvinhu zvinoparadza, zvichideredza zvakanyanya mukana wekuora, kunyanya munzvimbo dzine hunyoro uye dzinoparadza, iyi mhedzisiro yekudzivirira inonyanya kukosha.

Wedzera aesthetics. Iyo pamusoro pesimbi yakashongedzwa inoratidza silver-white metallic luster, iyo inovandudza kutaridzika kwechigadzirwa uye inokodzera zviitiko zvine zvakakwirira zvinodiwa zveaesthetics.

Inowedzera simba nekuoma. Iyo yakaoma alloy layer yakaumbwa panguva yekugadzira galvanizing haingogadziri kuoma kwepamusoro kwesimbi, asiwo inowedzera simba rayo.

Easy kugadzirisa. Simbi yakasvibirira ine nzvimbo yakatsetseka uye haisi nyore kuita ngura, ichiita kuti zvive nyore kucheka, weld, bend uye mamwe mabasa ekugadzirisa, izvo zvinovandudza mashandiro ekugadzirisa uye kunaka kwechigadzirwa.

Deredza mari yekugadzirisa. Pamusana pekukwirira kwekuora uye kusimba kwesimbi yakagadziriswa, kuwanda kwekugadzirisa uye kuchengetedza kunogona kuderedzwa mukushandiswa kwenguva refu, nokudaro kuderedza mari yose yekushandiswa kwenguva refu.

Wide range of applications. Simbi yakagadziriswa inoshandiswa zvakanyanya mukuvaka, simba remagetsi, kugadzira, kutakura uye mamwe minda nekuda kwekuita kwayo kwakanaka.

Pamusoro pezvo, kunyangwe galvanizing ine zvakawanda zvakanaka, inewo zvimwe zvayakaipira, zvakaita semitengo yakakwira yekugadzira, nyaya dzinobvira dzekusvibiswa kwezvakatipoteredza, uye dezincification inogona kuitika mune dzimwe nzvimbo dzakanyanyisa. Nokudaro, pakusarudza simbi yakakoswa, unofanirwa kufunga nezvezvakanakira zvayo, zvisingabatsiri uye zvakakodzera.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

The Stamping Process

Nzira yekutsikisa simbi inodaidzwa kuti kudhirowa kwakadzika inoshandiswa kuumba marata esimbi kuita maburi, axially symmetrical components. Iyi stamping process inonyanya kugadzira cylindrical shapes, kunyangwe ichigonawo kugadzira zvinhu zvakaita semabhokisi. Zvizhinji zvemaindasitiri uye zvemumba, senge sink, griddles, pombi dzemvura, zvikamu zvemotokari, zvinwiwa magaba, uye casings, zvinogona kuumbwa kuburikidza nekudzika kudhirowa kudhirowa.

Kushandisa punching simba, simbi simbi inodhonzwa radially kupinda kufa mukamuri iri mhando simbi stamping. Ndiro yesimbi inotanga kuiswa pachiumbwa chiri kuumbwa. Migumo yepepa inobatwa panzvimbo nekumanikidza kwemubati asina chinhu. Zvadaro, mechanical stamping tool inoshandisa axial force kune sheet simbi, ichibvumira workpiece kuti ipinde mugomba rekuumbwa uye inokanganisa mune yaunoda chimiro.

FAQ

Mubvunzo: Iwe uri kambani yekutengesa kana mugadziri?

A: Isu tiri mugadziri.

Q: Nzira yekuwana sei quote?

A: Ndapota tumira mifananidzo yako (PDF, stp, igs, nhanho ...) kwatiri ne email , uye utiudze zvinhu, kurapwa kwepamusoro uye huwandu, ipapo tichakuitira quotation.

Mubvunzo: Ndinogona kuodha chete 1 kana 2 pcs yekuyedza?

A: Hongu, hongu.

Q. Unogona kubudisa maererano sampuli?

A: Hongu, tinogona kugadzira nemasampuli ako.

Mubvunzo: Yakareba sei nguva yako yekuendesa?

A: 7 ~ 15 mazuva, zvinoenderana nekurongeka kwehuwandu uye maitiro echigadzirwa.

Q. Unoedza zvinhu zvako zvose usati wasununguka here?

A: Hongu, tine 100% bvunzo tisati tasvika.

Mubvunzo: Iwe unoita sei bhizinesi redu kwenguva refu uye hukama hwakanaka?

A:1. Isu tinochengeta mhando yakanaka uye mutengo wemakwikwi kuti tive nechokwadi chekuti vatengi vedu vanobatsirwa;

2. Tinoremekedza mutengi wese seshamwari yedu uye tinoita bhizinesi nemwoyo wose uye tinoita shamwari navo, pasinei nokuti vanobva kupi.