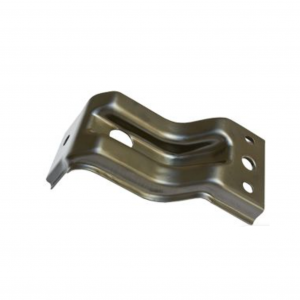

Chitambi chealuminium sheet metal parts

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Advantags

1. Kupfuura makore gumiyehunyanzvi hwekutengeserana mhiri kwemakungwa.

2. Ipaone-stop servicekubva pakugadzira mold kusvika kune chigadzirwa.

3. Kurumidza kuburitsa nguva, nezve30-40 mazuva. In stock mukati mevhiki imwe.

4. Yakasimba yemhando yekutonga uye maitiro ekugadzirisa (ISOcertified mugadziri uye fekitori).

5. Mimwe mitengo inonzwisisika.

6. Nyanzvi, fekitari yedu inekupfuura 10makore enhoroondo mumunda wesimbi stamping sheet simbi.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Profile yekambani

Semumwe wevanotungamira kuChina vatengesi vesimbi yakadhindwa simbi, Ningbo Xinzhe Metal Products Co., Ltd inotarisana nekugadzira zvikamu zvemotokari, zvikamu zvemichina yekurima, zvikamu zveinjiniya, zvikamu zveinjiniya zvekuvaka, zvishongedzo zvehardware, zvikamu zvemichina zvine hushamwari, zvikamu zvengarava, zvikamu zvendege, pombi fittings, maturusi ehardware, matoyi, uye zvemagetsi, pakati pezvimwe zvinhu.

Mapato ese ari maviri anowana kubva mukugona kwedu kunzwisisa zvizere musika unotarirwa uye kupa mazano anoshanda ayo anozobatsira vatengi vedu kuwana yakakura musika mugove. Isu takazvipira kupa vatengi vedu sevhisi yakatanhamara uye zvikamu zveprimiyamu kuitira kuti vawane kuvimba kwavo. Gadzira hukama hwekugara nevatengi vemazuva ano uye shingairira bhizinesi idzva munyika dzisiri dzekudyidzana kukurudzira kubatana.

Oxidation maitiro

Matanho anotevera anowanzo kuverengerwa mukuita oxidation:

1. Raw material feed: Shandisa mapaipi kuti upe zvinhu zvakasvibirira kune reactor kuitira kuchengetedza kuenzana kwakakodzera kwezvinhu zvakasvibirira mukati.

2. Kuita: Kuita oxidation reaction, wedzera oxygen kune reactor uye gadzirisa maitiro ekuita (senge tembiricha, kudzvanywa, uye kuita nguva).

3. Kupatsanurwa kwechigadzirwa: Shandisa inotonhorera yemhepo kuti utonhore chigadzirwa, uchishandura kubva munzvimbo ine gasi kuita mvura kana yakasimba fomu, uye ipapo shandisa separator kuparadzanisa zvigadzirwa zvinobva kune dzakasiyana siyana.

4. Kucheneswa: Kuve nechokwadi chekuti chigadzirwa chemaitiro chinosvika pakuchena kunodiwa, chichenese.

5. Packaging: Mushure mokunge zvigadzirwa zvacheneswa, zvinoputirwa maererano nemitemo nemitemo zvisati zvatengeswa kune vatengi kana kutumirwa kune imwe nhanho yekugadziriswa.

Mune mamwe maapplication chaiwo, akadai semiconductor wafer process, iyo oxidation process inosanganisirawo kupa oxidants (semvura, oxygen) uye kupisa simba pasilicon substrate kuumba silicon dioxide (SiO2) firimu. Iyi oxide firimu inodzivirira wafer nekudzivirira kuvuza ikozvino kubva mukuyerera pakati pemasekete, kudzivirira kupararira panguva yeion implantation process, uye kuita senge anti-etching firimu rinodzivirira kukanganisa kukanganisa panguva ye etching process.