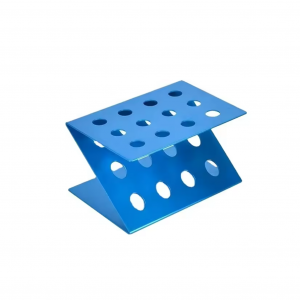

Tsika simbi Laser yekucheka kupeta Carbon simbi sheet simbi yekugadzira zvikamu

Tsanangudzo

| Product Type | customized chigadzirwa | |||||||||||

| One-Stop Service | Mold kuvandudza uye dhizaini-endesa sampuli-batch kugadzirwa-kuongorora-pamusoro pekurapa-kurongedza-kuendesa. | |||||||||||

| Process | kutsika, kukotama, kudhirowa kwakadzika, simbi yekugadzira simbi, welding, laser yekucheka nezvimwe. | |||||||||||

| Zvishandiso | kabhoni simbi, Stainless simbi, aruminiyamu, mhangura, galvanized simbi etc. | |||||||||||

| Dimensions | zvinoenderana nemifananidzo yemutengi kana sampuli. | |||||||||||

| Finish | Pfaya pendi, electroplating, inopisa-dip galvanizing, poda coating, electrophoresis, anodizing, blackening, nezvimwe. | |||||||||||

| Nzvimbo Yekushandisa | Auto zvikamu, zvekurima muchina zvikamu, engineering muchina zvikamu, kuvaka engineering zvikamu, gadheni accessories, zvakatipoteredza zvine hushamwari muchina zvikamu, zvikamu zvengarava, zvikamu zvendege, pombi fittings, Hardware tool parts, toy parts, electronic parts, etc. | |||||||||||

Stamping basics

Kutsika (kunonziwo kudzvanya) kunosanganisira kuisa simbi yakati sandara mucoil kana fomu isina chinhu mumuchina wekutsikisa.Muchidhina, chishandiso uye nzvimbo dzekufa zvinogadzira simbi kuita chimiro chaunoda.Kurova, kuvhara, kukotama, kutsika, embossing uye flanging ese ndiwo maitiro ekutsikisa anoshandiswa kugadzira simbi.

Zvinhu zvisati zvagadzirwa, nyanzvi dzekutsika dzinofanirwa kugadzira mold kuburikidza neCAD/CAM engineering.Aya madhizaini anofanirwa kuve akajeka sezvinobvira kuti ave nechokwadi chekubvumidzwa kwakakodzera kune yega yega punch uye kubhenda kune yakakwana chikamu chemhando.Chishandiso chimwe chete 3D modhi inogona kuve nemazana ezvikamu, saka maitiro ekugadzira anowanzo kuoma uye anopedza nguva.

Kana dhizaini yatemwa, vagadziri vanogona kushandisa akasiyana machining, kugaya, kucheka waya, uye mamwe masevhisi ekugadzira kupedzisa kugadzira kwayo.

Kutarisira kwehutano

Vickers kuomarara chiridzwa.

Chimbo chekuyera chimiro.

Spectrograph chiridzwa.

Chiridzwa chetatu chekubatanidza.

Shipment Mufananidzo

Production Process

01. Mold design

02. Mold Processing

03. Wire cutting processing

04. Mold kupisa kurapwa

05. Mold assembly

06. Mold debugging

07. Deburring

08. electroplating

09. Product Testing

10. Package

Mhando dzekukanda

Isu tinopa single uye multistage, inofambira mberi kufa, yakadzika dhizaini, fourslide, uye dzimwe nzira dzekutsikisa kuti ive nechokwadi chenzira inoshanda yekugadzira zvigadzirwa zvako.Nyanzvi dzeXinzhe dzinogona kuenzanisa purojekiti yako nekutsikirira kwakakodzera nekuongorora yako yakarodha 3D modhi uye tekinoroji kudhirowa.

- Progressive Die Stamping inoshandisa akawanda anofa uye nhanho kugadzira zvakadzika zvikamu kupfuura zvazvingawanzo kuwanikwa kuburikidza nekufa kwega.Iyo zvakare inogonesa akawanda geometries pachikamu sezvavanoenda kuburikidza nekufa kwakasiyana.Iyi tekinoroji yakanyatsokodzera vhoriyamu yepamusoro uye zvikamu zvakakura senge izvo zviri muindasitiri yemotokari.Transfer die stamping ibasa rakafanana, kunze kwekufambira mberi kwekufa kutsika kunosanganisira workpiece yakasungirirwa kune simbi tambo yakadhonzwa mukati memaitiro ese.Transfer die stamping inobvisa workpiece uye inoifambisa pamwe chete neconveyor.

- Deep Draw Stamping inogadzira zvitambi zvine makomba akadzika, semakona akavharirwa.Iyi nzira inogadzira zvimedu zvakaomarara sezvo iyo yakanyanyisa deformation yesimbi inomanikidza chimiro chayo kuita imwe crystalline fomu.Yakajairwa dhizaini stamping, iyo inosanganisira isina kudzika inofa inoshandiswa kugadzira simbi, inowanzoshandiswa.

- Fourslide Stamping inogadzira zvikamu kubva kumatemo mana pane kubva kune rimwe divi.Iyi nzira inoshandiswa kugadzira tunhu tudiki twakaoma kunzwisisa kusanganisira zvemagetsi zvakaita semabhatiri enhare.Kupa mamwe dhizaini kuchinjika, mitengo yakaderera yekugadzira, uye nekukurumidza nguva yekugadzira, fourslide stamping yakakurumbira muaerospace, zvekurapa, zvemotokari, uye zvemagetsi maindasitiri.

- Hydroforming ndiyo shanduko yekutsika.Mashiti anoiswa padhidhi ine chimiro chepasi, nepo chimiro chepamusoro chiri dundira remafuta anozadza kusvika pakumanikidzwa kukuru, achidzvanya simbi muchimiro chepasi kufa.Zvikamu zvakawanda zvinogona kuve hydroformed panguva imwe chete.Hydroforming inzira inokurumidza uye yakaringana, kunyangwe ichida chidimbu kufa kucheka zvikamu kubva papepa mushure.

- Blanking inocheka zvidimbu kubva papepa sedanho rekutanga usati wagadzira.Fineblanking, shanduko yekuvharika, inoita kucheka chaiko nemakona akatsetseka uye nzvimbo yakati sandara.

- Coining ndeimwe mhando yekuvharika iyo inogadzira madiki akatenderera workpieces.Sezvo ichibatanidza simba guru kuumba chidimbu chiduku, inoomesa simbi uye inobvisa maburrs uye mipendero yakaoma.

- Kurovera kunopesana nekuvhara;zvinosanganisira kubvisa zvinhu kubva pakushanda panzvimbo yekubvisa zvinhu kuti ugadzire workpiece.

- Embossing inogadzira matatu-dimensional dhizaini musimbi, ingave yakasimudzwa pamusoro pepamusoro kana kuburikidza nenhevedzano yekuora mwoyo.

- Kubhenda kunoitika pane imwe axis uye inowanzo shandiswa kugadzira maprofile muU, V, kana L maumbirwo.Iyi nzira inoitwa nekukochekera rimwe divi uye kukotamisa rimwe pamusoro pefa kana kudzvanya simbi mukati kana kurwisa kufa.Flanging ndiko kukotama kwematabhu kana zvikamu zvebasa rekushanda pachinzvimbo chechikamu chose.

Tight tolerances

Kunyangwe iwe uri muaerospace, mota, nharembozha kana indasitiri yemagetsi, yedu chaiyo simbi yekutsikisa masevhisi anogona kuendesa chikamu chimiro chaunoda.Vatengesi vedu vanoshanda nesimba kuti vasangane nezvinodiwa zvako zvekushivirira nekushandisa iterating chishandiso uye mold dhizaini kuti inyatso kuburitsa kuzadzisa zvaunoda.Zvisinei, iyo yakasimba kushivirira, iyo inonyanya kuoma uye inodhura.Precision simbi zvidhindo zvine kushivirira kwakasimba zvinogona kuva mabhuraketi, zvimedu, zvinopinza, zvinobatanidza, zvishongedzo uye zvimwe zvikamu mumidziyo yevatengi, magidhi emagetsi, ndege nemotokari.Iwo anoshandiswawo kugadzira ma implants, midziyo yekuvhiya, tembiricha probe uye zvimwe zvekushandisa zvekurapa zvikamu zvakaita sedzimba uye zvikamu zvepombi.

Kugara uchitarisa mushure mekumhanya kwega kwega kunotevedzana kuti uone kuti kuburitsa kuchiri mukati meiyo dhizaini kwakajairwa kune ese zvitambi.Hunhu uye kuenderana chikamu cheyakazara kugadzirwa kwegadziriso chirongwa chinotarisisa chidhindo chezvishandiso kupfeka.Zviyero uchishandisa inspection jigs zviyero zvakajairwa pamitsetse yakareba-inomhanya mitsetse.